About us

Our company

Welcome to the new era of sustainable and powerful protection for your prized watercraft with our cutting-edge, eco-friendly custom boat fenders!

Designed specifically for shipyards, boat builders, tender boat builders, RIB boat builders, military patrol boats, coastguard patrol boats, police boats, and rescue boats - we've got you covered.

Why Choose Our Custom Boat Fenders?

- Sustainable and Eco-friendly: Our revolutionary boat fenders are made from environmentally safe materials, ensuring minimal impact on the aquatic life.

- Unmatched Protection: Expertly designed to deliver maximum protection against all types of impacts, safeguarding your valuable marine investment from potential threats 24/7.

- Customized Solutions: Overcome unique challenges faced by different types of watercraft with our bespoke designs engineered to meet your specific needs - from military vessels to rescue boats.

- Durable and Long-lasting: Built with high-quality materials and state-of-the-art manufacturing processes, our fenders are tough enough to withstand harsh weather conditions and prolonged sun exposure without losing efficiency.

- Commitment to Excellence: As an industry leader, we take pride in providing attentive customer service and ensuring absolute satisfaction with every product we deliver. Experience the unmatched protection.

Discover New Fender Solutions

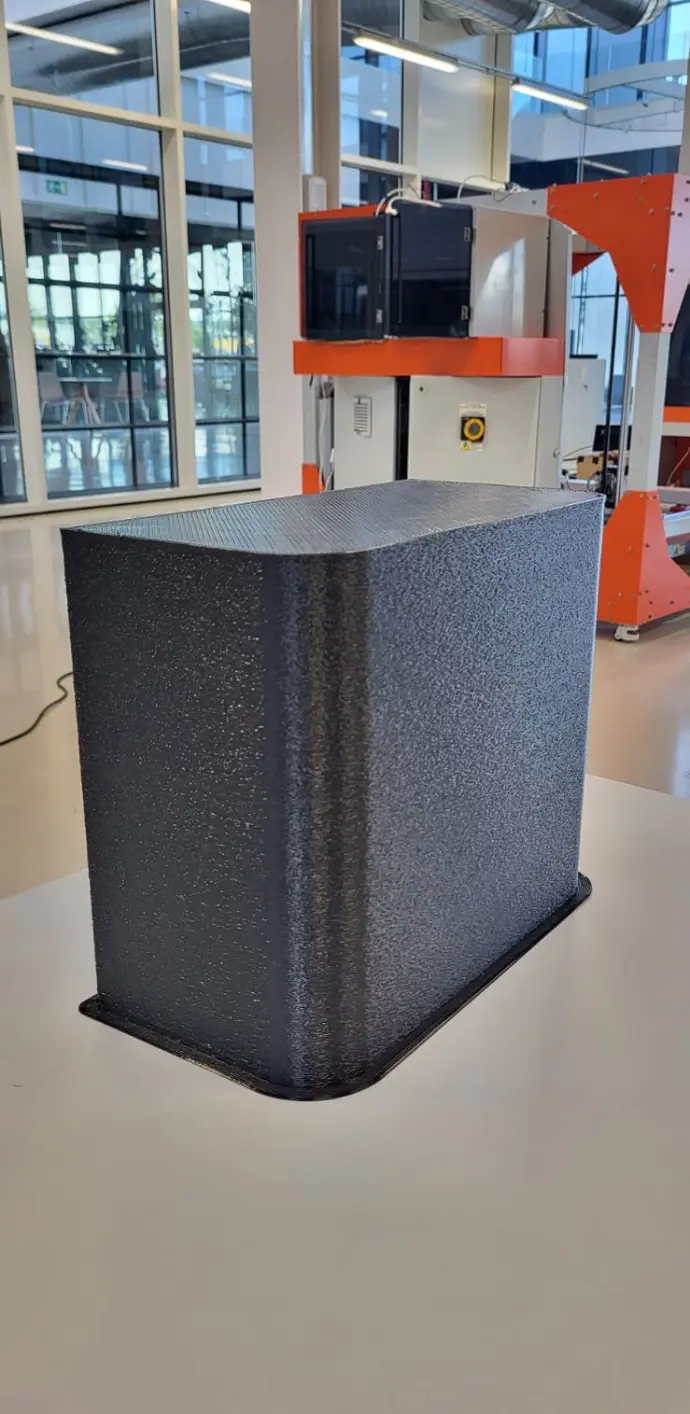

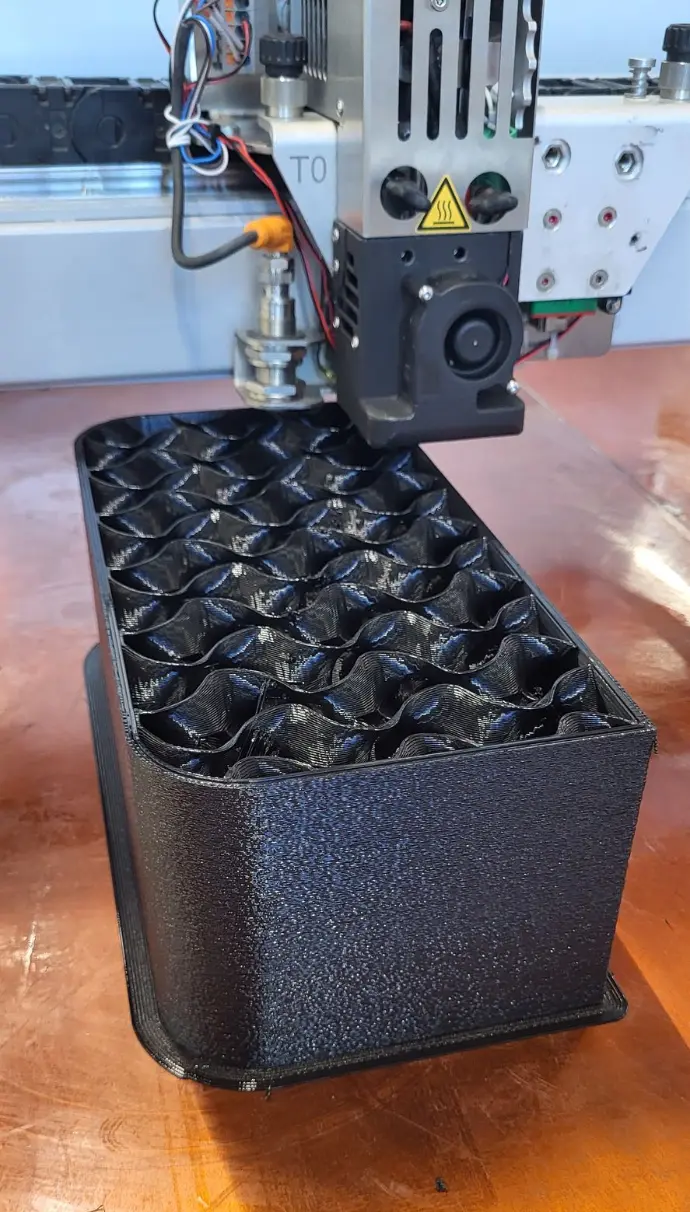

3D Printed Solution for Marine Fenders

Traditional marine fenders are heavy, costly to produce, and often made from materials that harm the environment. With large-format 3D printing, we’re transforming this essential piece of maritime equipment into a sustainable, customizable, and highly efficient solution.

Our 3D-printed fenders are produced with advanced elastomers polymers, designed to absorb impact while reducing weight and waste. This technology allows us to:

Customize on demand: Any size, shape, or branding can be integrated directly into the fender design.

Improve performance: Optimized geometries and internal reinforcement provide better shock absorption compared to conventional products.

Reduce environmental impact: By using recyclable and bio-based materials, we minimize CO₂ footprint and extend product life cycles.

Accelerate production: What once required weeks of tooling can now be printed in days with no molds or excess material.

3D printing isn’t just a new manufacturing method—it’s a complete rethinking of how we protect boats, ports, and the marine environment.

With our fenders, you can safeguard your vessels and structures from damage.

Experience the difference in quality.

Meet our team

Dedicated experts ensuring your satisfaction

Main Head quarter

Fernando Fortunato

Chief Technology Officer

ff@newsfender.com

+34 665 21 30 66

Hector Carreras Cejudo

Mechanical Engineer

Mark Saric

Head of Sales

ms@newsfender.com

+34 660 22 06 46

Marc Ribas

Operations

USA HQ

Dedicated professionals driving our success